OUR COMMITMENT TO QUALITY

Advanced Design and Manufacturing at Long Range Automotive

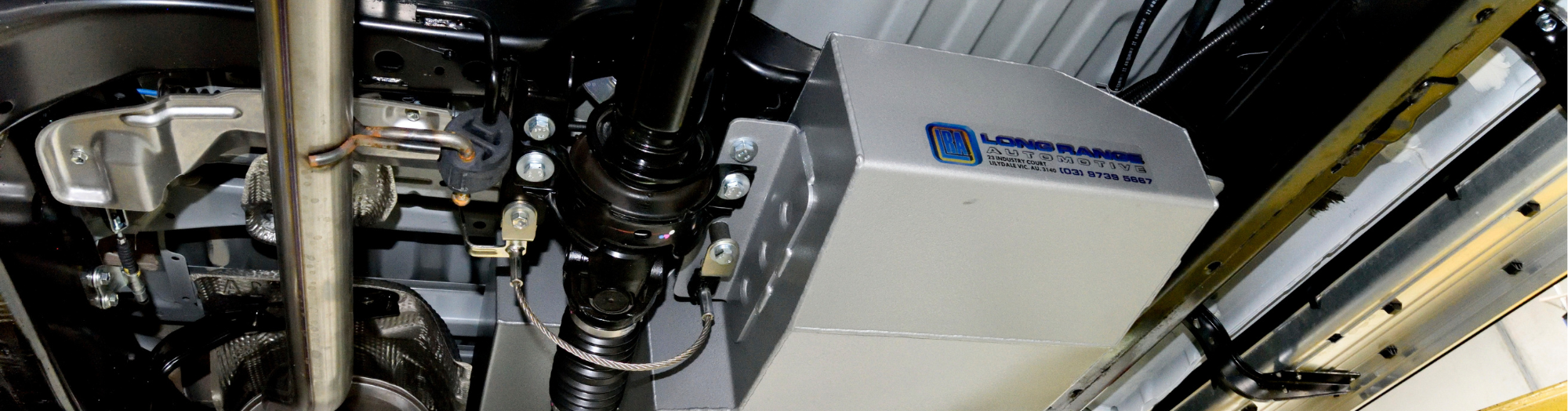

At Long Range Automotive, we leverage cutting-edge 3D modeling software to create optimal designs tailored to specific vehicles. Our precision CAD 3D models and drawings ensure that every fuel tank fits seamlessly in the designated location.

We utilize the state-of-the-art 'HyPertherm HyPerformance' CNC plasma profile cutting system, equipped with 'True Hole' technology. This advanced method guarantees exceptional accuracy, resulting in high-quality, precision-engineered fuel tanks for our customers.

All welds on our long-range fuel tanks are performed using full penetration MIG welding, employing high-quality inert shielding gas and layered MIG wire. This technique ensures superior welding penetration and minimizes porosity. Our tanks are designed with full internal baffling and incorporate an expansion chamber, enhancing their durability. Each tank undergoes rigorous pressure testing and is subject to two separate quality control checks.

We are committed to using only the finest materials, including 2mm (14 gauge) T125CQ aluminised sheet steel, brass threaded hose barb fittings, stainless steel hose clamps, and high-tensile bolts with nyloc nuts.

At Long Range Automotive, we prioritize delivering products of the highest standard, ensuring reliability and complete customer satisfaction.

Long Range Automotive

23 Industry Court, Lilydale VIC 3140 Australia

PH: +61 3 9739 5667